친환경 원료소개 - 실험결과

바이오 플라스틱의 실험실 및 자연 환경내 산화생분해 시험 결과

PE 베이스 바이오 필름의 생분해성 - ASTM G21, SEM

|

|

|

| Polyethylene film | Bio-based film(PE) | Biodegradable film |

PE 베이스 바이오 필름의 생분해성 - ASTM G21, SEM

|

|

|

| Polyethylene film | Bio-based film(PP) | Biodegradable film |

실험실 테스트 결과 - SEM

|

| Experiment start |

|

| After 1 week |

|

| After 2 week |

- PE 필름, 바이오 베이스 필름, 생분해 필름을 ASTM 방법에 따라 탄소원(Carbon source)을 제외시킨 미생물 배양배지에서 실험한 결과, 바이오 베이스 및 생분해 필름에서는 미생물이 성장하여 미생물에 의한 분해를 확인하였다.

- 배양배지에 탄소원을 제외시켰기 때문에 시료 필름을 분해하여 탄소원을 보충하면 미생물이 성장하고 분해를 못시키면 미생물이 성장하지 못한다.

*Reference*

- "Manufacturing Multi-degradable Food Packaging Films and Their Degradability" Korean J. Food Sci. Technol, 35(5), p877-883, 2003

- "Degradability of Multi-Degradable HDPE and LDPE Food Packaging Films" Food Sci. Biotechnol., 12(5), p548-553, 2003

- "Studies in the Development of Biodegradable Plastics and Their Safety and Degradability" Food Engineering, 15(3), p257-261, 2011

- "Development of Oxo-biodegradable Bio-plastics Film Using Agricultural By-product such as Corn Husk, Soybean Husk, Rice Husk and Wheat Husk, 20(3), 2014

바이오 플라스틱의 실험실 및 자연 환경내 산화생분해 시험 결과

|

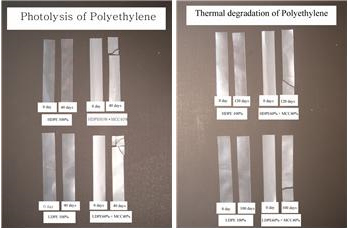

Pictures of PE base bio films after UV and heat treatment

|

|---|---|

|

Changes in elongation of PE based bio film during heat Treatment(68±2℃, RH 85%)

|

|

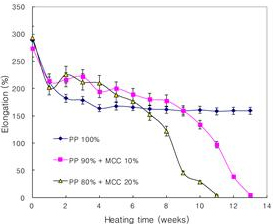

Changes in elongation of PP based bio film during heat Treatment(68±2℃, RH 85%)

|

*Reference*

- "Multi-degradable Food Packaging Plastics Prospect of Their Pactical Use" Food Engineering Process, 7(3), p134-140, 2003

- "Assessment and Applications of Multi-Degradable Polyethylene Films as Packaging Materials" Food Sci. Biotechnol., 15(1), p5-12, 2006

|

Pictures of PE base bio films after UV and heat treatment

|

|---|

Changes in elongation of PE based bio film during heat Treatment(68±2℃, RH 85%)

- Black : width

- Pink : length

|

Changes in elongation of PP based bio film during heat Treatment(68±2℃, RH 85%)

|

|---|

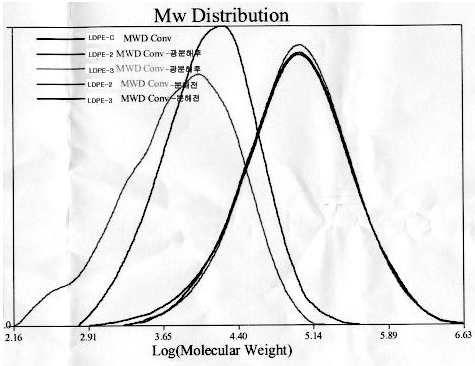

분자량 감소 실험, 적외선 분광 결과

-

(1) 분자량 감소 실험 결과

자외선, 열 등의 외부자극에 노출시키지 않은 필름에서는 1710 ~ 1750cm-1의 카르보닐(carbonyl)됨을 확인하였다. 수십만의 고분자량의 폴리머는 분해 후의 경우 10,000 ~ 20,000정도로 감소하였으며, 열 및 UV에 의한 분해의 경우는 분자량이 7,800 ~ 8,000으로 감소되었다. 저분자화 된 필름은 미생물에 의하여 분해될 수 있으며, 이는 바이오매스 필름의 생분해 특성을 확인시켜주는 실험결과이다.

-

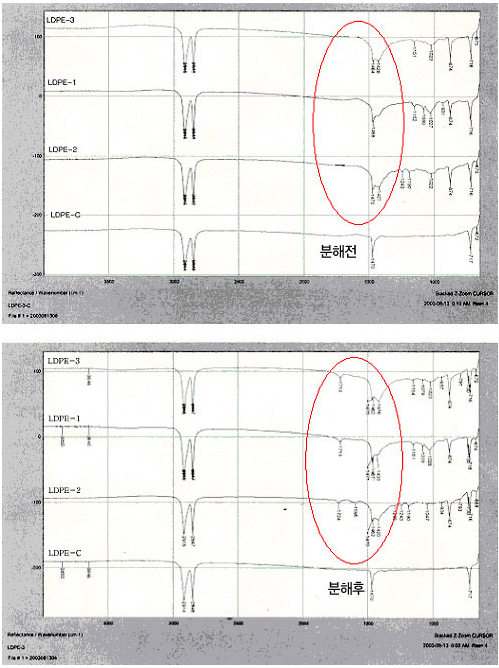

(2) 적외선 분광 실험 결과

분해후 필름제품의 중량 평균 분자량 분포가 크게 낮게 위치하고 있었으며, 장쇄 고분자가 저분자화 흡수대를 관찰할 수 없는 반면, 40일간 광 노출 후의 필름과 120일간 열 노출된 필름에서 카르보닐 흡수대를 관찰할 수 있었다. 카르보닐기는 플라스틱이 분해되는 과정에서 생성되는 물질이다.

* 출처 *

“복합분해성 식품포장용 플라스틱”, 산업식품공학

- Food Engineering Process, 7권 3호, p134-140. 2003. 8. Chung, M.S., Lee, W.H., You, Y.S., Kim, H.Y., Park, K.M., and Lee, S.Y. 2006. Assessment and Applications of Multi-Degradable Polyethylene Films as Packaging Materials. Food Sci. Biotechnol., 15(1) : 5-12. Scott, G., Ed., 1993, Atmospheic Oxidation and Antioxidants, Elsevier, London.

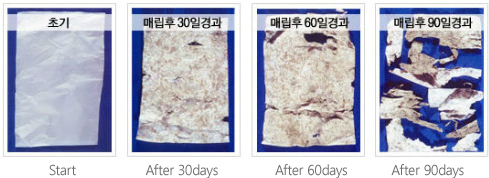

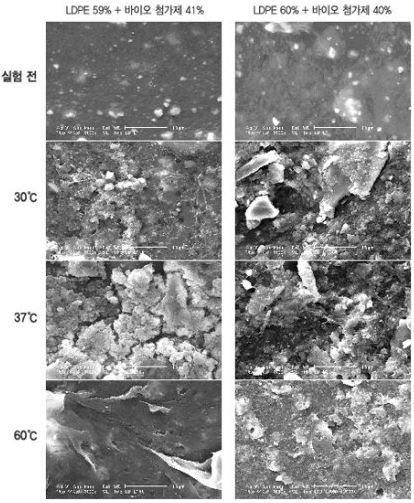

모의 토양 매립 시험 결과

온도와 습도가 조절된 모의 매립 환경에서 산화생분해제를 구성하는 성분들의 혼합비를 다르게 한 필름을 6개월간 노출시킨 결과 생분해 물질이 분해되어 다공성 상태가 되고 분자량이 저하되는 것을 확인하였다.

- 성균관대, 가톨릭대 공동연구 연구결과

- 농기평 연구과제 결과(연세대, 한국식품연구원 등)

|

매립실험

|

|

멀칭 테스트

멀칭 필름

- 제조공정 : 생분해 및 바이오 첨가제 펠렛 >압출(필름 완제품)

- 제품의 특장점 : 분해기간 조절-작물생육기간 연계 > 기후, 온도, 토양 유기물량, 토양 수분 등에 민감하다.

| 구분 | 미생물 배양실험 ASTM G20 38도, 30일 배양SEM 1000배 사진 |

멀칭 실험 농업진흥청 포장실험고추 멀칭(7개월) |

|---|---|---|

| 일반 플라스틱 |  |

|

| 자연분해 플라스틱 |  |

|

| 생분해 플라스틱 |  |

|

해외 제품과의 비교 시험 결과

좌측이 본사 제품의 분해결과가 해외 C사 대비 분해성이 우수하다. 광주 원예농협 시험장에서 9개월간 시험한 결과이다.

|

비분해 멀칭, 당사 2종, 해외 광분해 2종, 해외 생분해 2종 및 해외 복합분해 1종 합계 8종의 멀칭필름을 시험군으로 하여 농촌진흥청 국립농업과학원에서 7개월동안 비교 실험한 결과이다. |

|---|

(1) 실험 시작후 3개월 경과

(2) 실험 시작후 7개월 경과

|

|

|

|

| 비분해 | 당사 I | 해외 광분해 I | 해외 광분해 II |

|

|

|

|

| 해외 생분해 I | 해외 생분해 II | 해외 복합분해(산화생) | 당사 II |

성균관대, 서강대 공동연구 결과

바이오 재질 멀칭 필름의 야외실험

|

|

|

| 실험시작 | 60일 경과후 | 90일 경과후 |